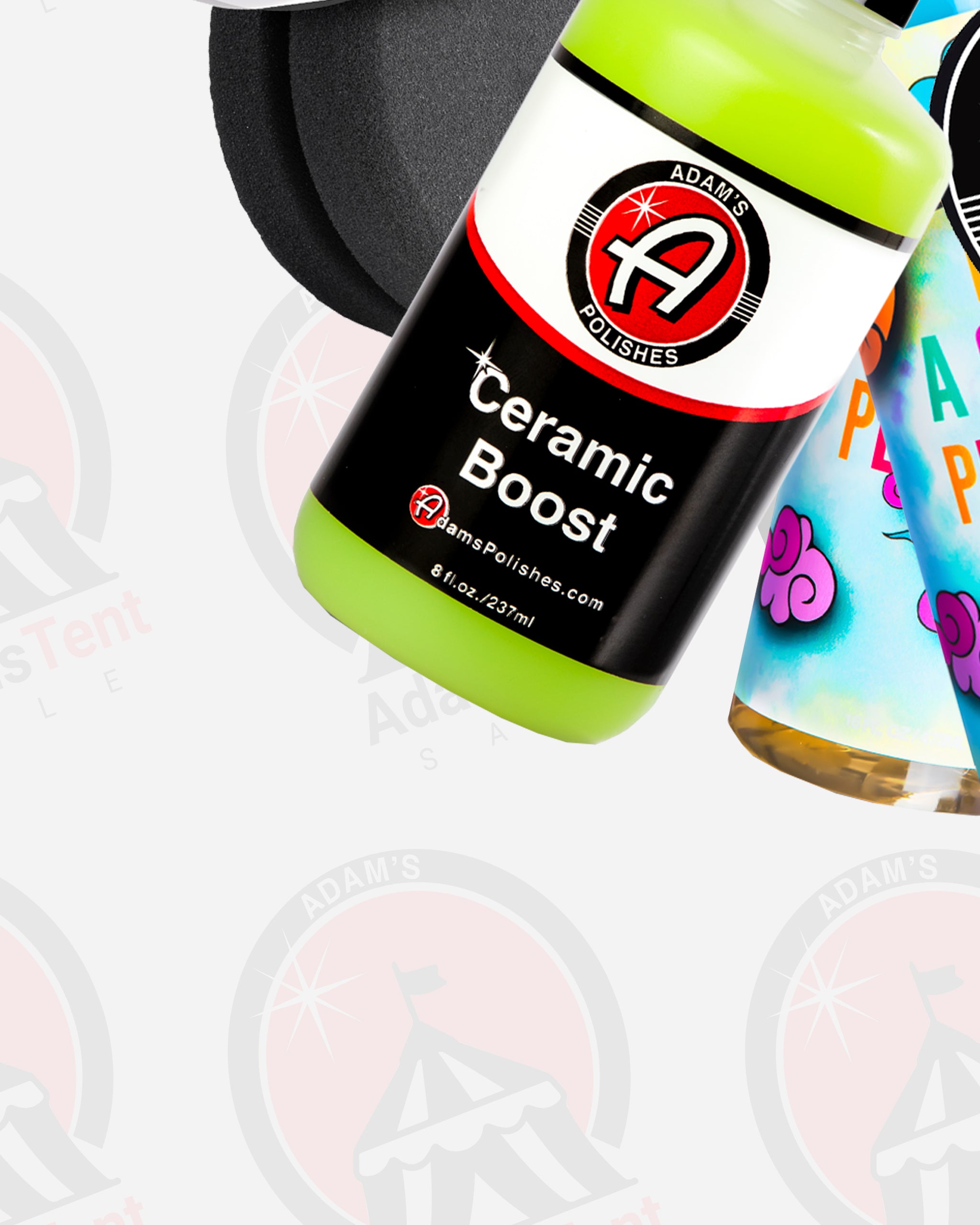

Ceramic Coating (OLD Version)

Final Sale, No Returns Or Exchanges.

Adam’s Ceramic Coating is a simple, ready to use system that combines versatility with ease of use.

- Provides long-lasting protection

- Easy application process

- For Use On Plastic Trim, Headlights, & Other Exterior Plastics

- Darkens Trim

- Can Be Layered Over Black Trim Restorer

- 50ml Bottle

We currently offer free shipping in the continental US on orders over $75 after discounts or $7 Flat Rate Shipping. If you don't love what you receive, we'll cover shipping back to our door too. Please note, free returns are not included on international orders.