How To Video:

Introduction Video:

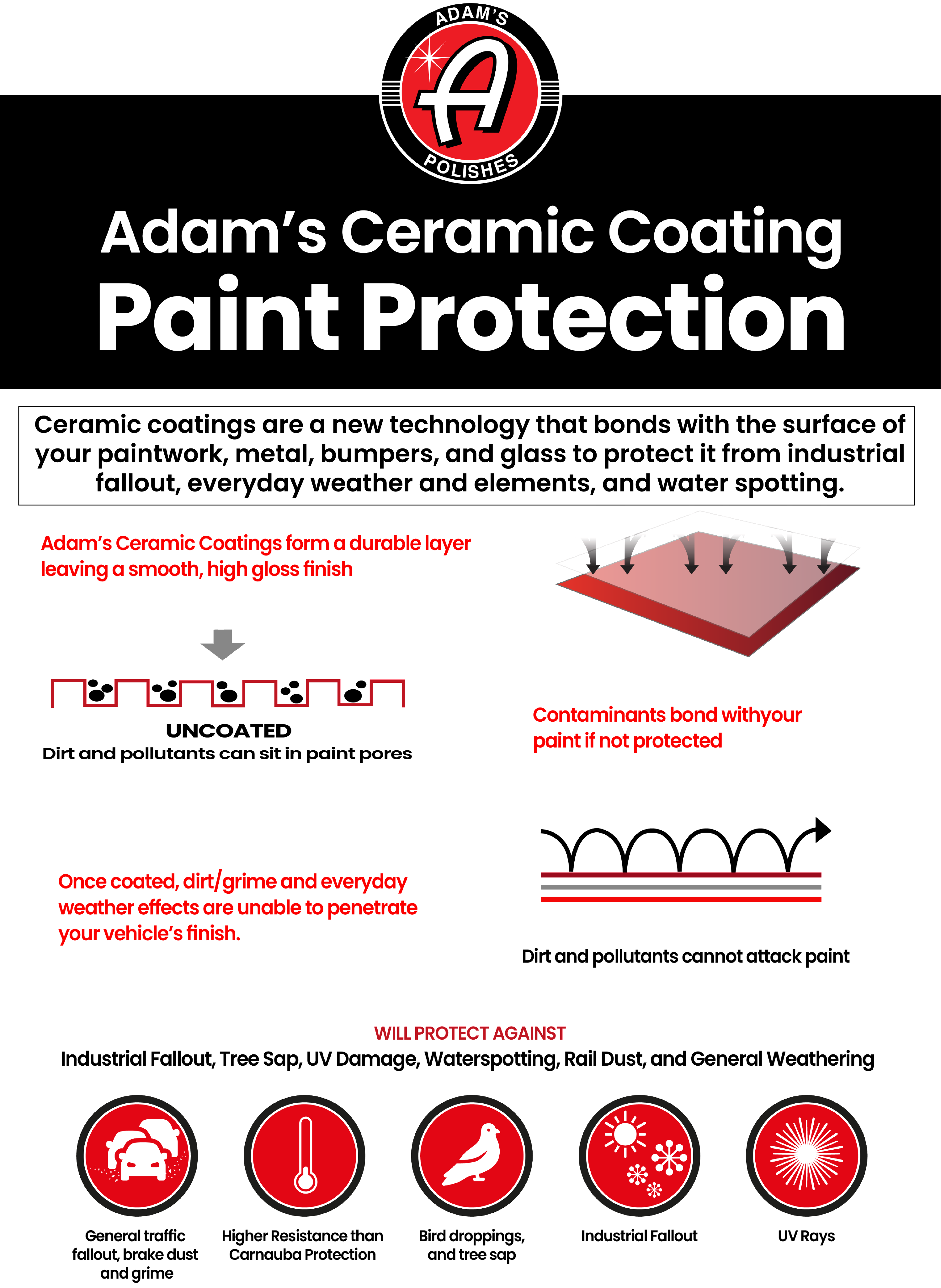

Adam’s Ceramic Spray Coating, a game changing product in the ceramic coating world. At a registered 9H Hardness, Adam’s Ceramic Spray Coating is the easiest and fastest way to ceramic coat your vehicle and add unbelievable shine and gloss to your finish. Since ceramics have been introduced to the market, consumers and manufacturers alike have had to jump onboard and introduce the chemistry of ceramics into their product lines. Here at Adam’s Polishes, we wanted an easier way to provide our customers our newly improved ceramic paint, wheel, and trim coating options into a sprayable application. Using the most unique and user friendly chemistry on the planet, weekend hobbyists and detailing enthusiasts can add ceramic protection to the their finish, wheels, plastic components, trim, and glass in minutes.

Let’s set something straight… In the car care industry, ceramic coatings and “nano” technology have become buzz words and industry standards and although sometimes effective, these are not true “ceramic” coatings. Having silica resins, or “containing SiO2” doesn’t make it a true ceramic coating. Containing ceramic technology is the minimum to passing the first audition in modern car care, but is it an actual ceramic coating? Unfortunately, no. Consider our Ceramic Boost or Ceramic Paste Wax: Both contain heavy amounts of SiO2, give extreme amounts of gloss and protection, and are extremely hydrophobic, but not actual coatings! They are designed for ceramic maintenance in between washes, or an alternative to conventional carnauba/polymer waxes. With Adam’s Ceramic Spray Coating, the proof is in the application— The first swipe of the product will reveal a quickly appearing “rainbow” effect, theres your proof! This is not a streak, smear, or defect— The rainbow effect is a mixture of gases and liquids evaporating and curing to your finish to provide the hydrophobic, acid-resistant, water spot-resistant, and UV inhibiting layer that we’re all after. As the rainbow effect begins to widen and develop, the applied product is turning to evenly hardened SiO2, or glass— hence “glass” coatings. Now, this chemistry is unique to the sprayable coating versus our current coatings as it has a longer working time, allowing it to tack up not as quickly and let you cover an entire hood, as opposed to small sections or proportions.

What makes a ceramic coating, a ceramic coating?

Hang tight, we’re going to get scientific with you— Ceramic coatings start with silica resins, ones that are usually cured in a furnace or extreme heat, but are modified versions to cure at room temperature (ie your garage or detail shop!).

The ceramics we’re used to are the modified versions and are neatly ordered and paired molecules of Si and O that make a tetrehedron, which produces a perfect triangle contributing to its stability and strength on your paint. The Si and O molecules are so strong in fact that their bonds don’t step out unless abrasion and/or heat are introduced, hence why Ceramic Coatings only come off with time or accelerated polishing!

When developing this product, we wanted to make sure this product could be used in any situation or climate. Both high humidity areas, and dry areas like our headquarters in Colorado were prominent areas of testing grounds and application, and produced exceptional results on all accords.

“6-8 months? How come it doesn’t last as long as your current paint coating?” So with this new chemistry, we made it pretty easy for application… almost a little too easy! With ceramic coatings, you have a hardness that the ceramic cures to, the hardest measured test being 9H to truly be accredited by the SGS (until they find a 10H hardness pencil at least!). The hardness doesn’t mean how it long it lasts though, but the easiest way to think of this is like a stack of paper towels vs one single sheet. Paper towel doesn’t become stronger or tear-proof as you stack it, maybe a bit more absorbent, but the strength doesn’t change. With Ceramics, particularly our paint and wheel coatings, both are 9H but create different film thickness layers (how many stacks of paper towels high). Paint creates a relatively thin layer, conserving the gloss, shine, and uniqueness of your finish— whereas Wheel creates a thicker layer for heat resistant, reduced brake dust adhesion, and overall increased longevity. With Adam’s Ceramic Spray Coating, the chemistry is unique for the delivery method creating a thin layer of ceramic protection with each wipe! The ease of use and low-level tackiness go hand in hand.

Frequently Asked Questions

“How do I prep my paint for this product? How can I ensure I’ll get the maximum longevity out of it?" If your paint is bare and ready for a protective coating, you’ll want to clay your car at minimum to remove any bonded contaminants. This not only will give you that silky smooth feeling we all love and enjoy, but it will also cleanse the paint of any bonded surface contamination that will hinder the coating from bonding to the surface. Once clayed, simply use an IPA based prepping agent, or our Surface Prep, and coat the desired area once finished. For optimum results, we recommend perfecting your paint by removing any swirls, oxidation, or water spots using our Swirl Killer Polishing System.

“Can Ceramic Spray Coating be applied over my current wax or sealant?” The short answer is no. For optimized results, we recommend stripping the surface before coating. Use a Fine Grade Clay Bar and Detail Spray, followed with Surface Prep. Since our waxes and sealants are great forms of protection, the coating will be partially rejected during the bonding process and hinder the duration and longevity of this coating.

“What if my car is already Ceramic coated?” If your car is already coated, you’ll want to use a Fine Grade Clay bar and Detail Spray to remove any surface contamination. Then, apply a few mists of Surface Prep to remove any surface oils or residue— Finally, apply the coating by spraying it into your microfiber towel and treating the surface desired. 1-2 Minute Flash Time, 4 Hour No-Touch-Time.

“How come Ceramic Spray Coating doesn’t last as long as your current Ceramic Paint Coating?” With this new chemistry, we made application extremely easy. When it comes to ceramic coatings, you have a hardness that the ceramic cures to, the hardest measured test being 9H to truly be accredited. The hardness doesn’t mean how long it lasts though, but the easiest way to think of this is like a ream of paper vs one single sheet. Paper doesn’t become stronger as you stack it. Ceramics coatings, particularly our paint and wheel coatings, are both 9H but create different film thickness (how many stacks of paper high). Ceramic Paint Coating creates a relatively thin layer, conserving the gloss, shine, and uniqueness of your finish— whereas Ceramic Wheel Coating creates a thicker layer for heat resistant, reduced brake dust adhesion, and overall increased longevity. With Adam’s Ceramic Spray Coating, the chemistry is unique for the delivery method creating a thin layer of ceramic protection with each wipe!

“If it’s 9H, why isn’t it the same as Ceramic Paint Coating?” With ceramic coatings, once you apply the ceramic to the surface the ceramic starts to flash and cure, building up a layer of protection. Once it is dry or cured, the hardness it cures to is 9H. Think of it as a sheet of paper, versus an entire ream— The sheet of paper would be the 9H hardness, and how thick the ream of paper is would be how thick the ceramic develops and cures to.

“Can I layer this product to make it last longer?” Yes, of course, but that doesn’t mean layering this product 10 times will make it 10x longer. More than 3 applications will render the product redundant and still provide the same hydrophobic effects.

“What surfaces can I use Ceramic Spray Coating on?” Adam’s Ceramic Spray Coating provides protection to an extreme range of areas on your vehicle. Paint, Wheels, Glass, Headlights, Plastic trim, Bed liners, Tonneau covers, Canvas tops, Floor mats, Unfinished metal— All can be protected with Ceramic Spray Coating. We strongly recommend that you apply the product panel by panel to ensure thorough application and as much control of overspray as possible.

“How long do I have to wait for Ceramic Paint Coating to cure?” Since this product is dispensed through a sprayer, it starts curing as soon as you start to pull the trigger and the product flows onto the towel! Once it’s applied to the surface intended for treatment, let it rainbow and “flash” for 1-2 minutes, then remove with a microfiber towel. After the treatment is applied, you’ll want to keep it safe and element-free for about 3-4 hours.

“Can I reuse my Microfiber towels after being used with Ceramic Spray Coating?” Treat your towels as you would with any other coating. With Ceramic Spray Coating, you have bought yourself some extra time since it's so thin, but that doesn’t mean it doesn’t crystalize and harden over time. If you apply the coating and then toss the towels in the washing machine, you’ll remove most of the residual coating in the towel. The longer you expose your towels to oxygen, the more susceptible it is for crystallization. If you coat your car, then leave the towel overnight perhaps, then you might have a tougher time removing the coating from the microfibers.

“If I have Ceramic Paint Coating on my car, and want to top it with Ceramic Spray Coating, Ceramic Paste Wax & Ceramic Boost, how do I layer them?” Ceramic Paint Coating should always be applied first since it’s the thickest layer. Ceramic Spray Coating should then be applied additionally and allowed to cure for 4 hours. If desired, you’ll want to top it with Ceramic Paste Wax first, then Ceramic Boost if you’re wanting the maximum shine we are currently able to offer!

“What happens if I forget to remove a spot or end up with a high-spot?” Adam’s Ceramic Spray Coating does have a slight self-leveling agent built into the formula for ease of use, but we know that accidents happen. If you forget a spot and you catch it in time (10-20 minutes after removal) simply apply to that area and wipe off after 1-2 minutes. Reactivating the product will allow for easier removal. If left on for longer, we recommend Brilliant Glaze and a microfiber applicator, or machine polishing with Correcting Polish to fully remove the imperfection.

“Can I use this on Matte/ Satin Paint or Vinyl Wraps? Will it make it glossy?” You can use this on Matte and Satin finishes. It will add increasingly better depth and sheen to the surface, but will not make it shiny! As this coating will flash on a clear coat, window, or gloss surface, you will not get flashing but still need to level off the coating as it will look streaky and smudgy in appearance upon application.

“Can I use this on my interior?” No. This product is recommended for use on exterior surfaces and because of the strong odor, we do not recommend use for this on any interior surfaces.