Graphene Ceramic Coating™ Advanced

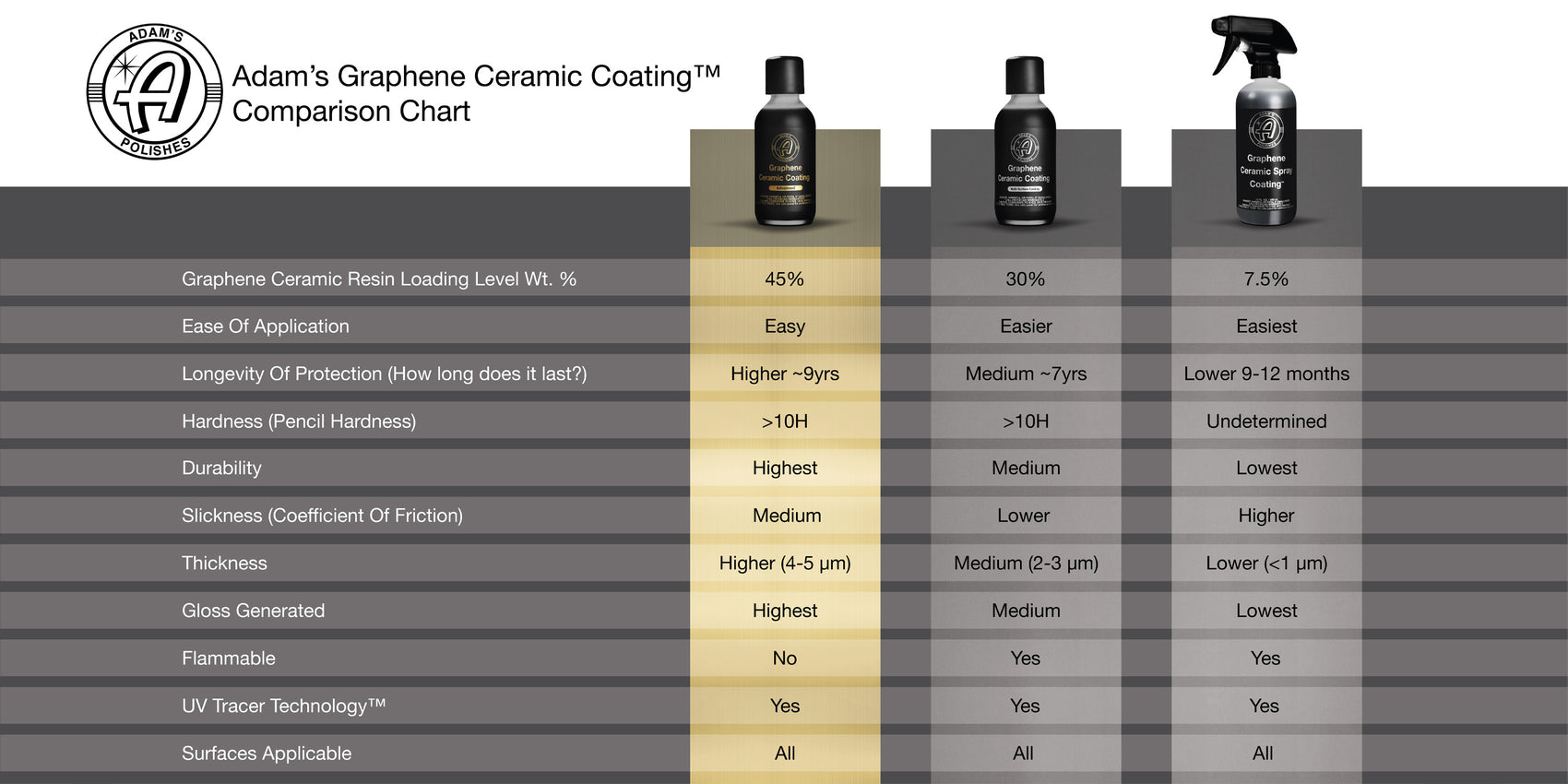

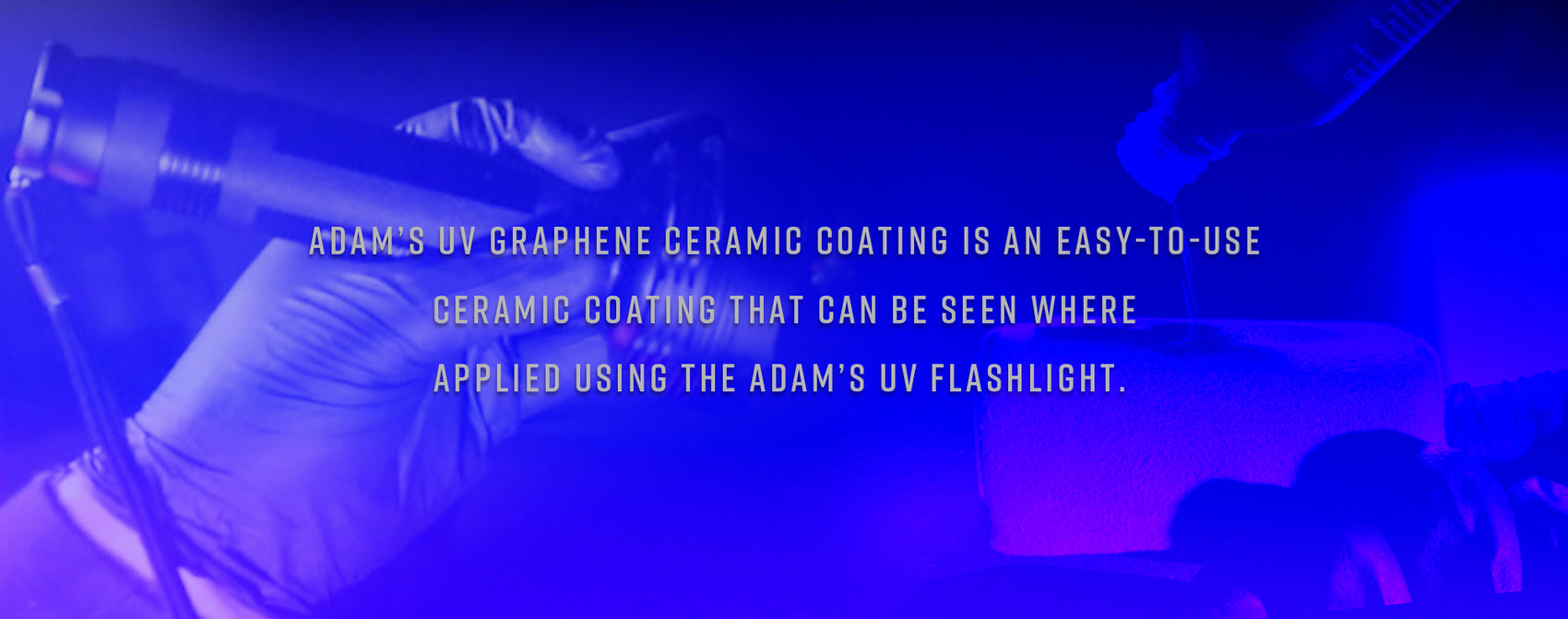

Adam’s Graphene Ceramic Coating™ Advanced is an easy-to-use Ceramic Coating that can be seen where applied using the Adam’s UV Flashlight and our patent-pending UV Tracer Technology™. With improved characteristics, this coating is appropriate to add long-lasting, extreme self-cleaning effects for single-stage and clear-coated, painted surfaces, glass, plastic trim, polycarbonate, rubber moulding, and wheels with a single bottle.

- >10H Hardness, 9+ Years of Protection

- 50% Increased Coating Resin Over Graphene Ceramic Coating™

- Inclusion of Additional Silicate Resin for Added Durability and Longevity

- Less prone to water spotting

- Higher stain resistance against bugs, saps, droppings, etc.

- Higher scratch resistance during the washing process

- Increased depth and clarity to all surfaces

- Lower sliding angle with water evacuating at angles less than 10-15°

- Higher contact angles averaging more than 110-118°

- Patent Pending, UV Tracing Technology™

- Free to apply to all Painted Surfaces, Glass, Headlights, Chrome, Trim, Wheels, and even Bed Liners!

We currently offer free shipping in the continental US on orders over $75 after discounts or $7 Flat Rate Shipping. If you don't love what you receive, we'll cover shipping back to our door too. Please note, free returns are not included on international orders.

In the kit you’ll find:

1- 60ml Graphene Ceramic Coating Advanced

1- 4oz Graphene Boost

1- 4oz Surface Prep

2- Single Soft Towels

2- Suede Removal Towels

2- Suede Applicators

1- Pair of Gloves

Optional 1- UV Flashlight

Instructions for Paint & Glass:

- Prepare your painted surface or glass by using the supplied 4oz bottle of Adam’s Surface Prep and Surface Prep towel to clean and degrease the surface of any existing protection or residual films. For optimal results, users must Wash, Clay/Decontaminate, and Polish their paint prior to application.

- Shake coating bottle before use. Open the coating bottle and begin by dispensing numerous drops of the liquid onto the supplied Micro Silk applicator to sufficiently wet it. Work the product into the surface, ensuring full coverage over the desired area, using cross hatching motions and overlapping your previous pass by 25-50%. During your time between passes, utilize Adam’s UV Flashlight for inspections. Take note of between the body lines, bumper areas, mirror caps, and commonly missed areas on your vehicle. To ensure a thorough application, the light should shine and reveal an even and consistent bluish hue of light. If you notice streaking in the surfaces, level out with additional product and the used Micro Silk applicator.

- Once the recently applied product begins to characteristically flash and sweat into beads, begin wiping the coating off, applying minimal pressure to the towel in the process. Wipe down in a similar cross hatch pattern as applied, switching/flipping the towel periodically to use a new face to fully level the coating.

- Once fully leveled, allow the coating to fully cure for 24 hours, free from water, elements, or weathering.

Instructions for Plastic Trim & Headlights:

- Prepare your plastic trim or headlights by using the supplied 4oz bottle of Adam’s Surface Prep and edgeless utility towel to clean and degrease the surface of any existing protection or residual films. For heavily contaminated plastic trim or headlights, we recommend a deep cleanse with Tire & Rubber Cleaner and an edgeless utility towel.

- Open the coating bottle and begin by dispensing numerous drops of the liquid onto the supplied Micro Silk applicator to sufficiently wet it. Work the product into the surface, ensuring full coverage over the desired area, using cross hatching motions and overlapping your previous pass by 25-50%. Since the product is being applied to a porous surface, you will not see a rainbow/ flashing effect - the immediate color change of the plastic or trim will reveal where the product has been applied. However, you are also able to utilize the Adam’s UV Flashlight for inspections where desired.

- Once the recently applied product has penetrated, begin leveling the coating, applying minimal pressure to the towel in the process. Wipe down in a similar cross hatch pattern as applied, switching/flipping the towel periodically to use a new face to fully level the coating.

- Once fully leveled, allow the coating to fully cure for 24 hours, free from water, elements, or weathering.

Instructions for Wheels:

- Prepare your wheels by using the supplied 4oz bottle of Adam’s Surface Prep and edgeless utility towel to clean and degrease the surface of any existing protection or residual films. For heavily contaminated wheels, we recommend a thorough cleaning with Adam’s Wheel Cleaner, or Eco Wheel Cleaner, in addition claying with a Fine Grade Clay Bar and Detail Spray may also be necessary to initially remove stubborn contaminations from the barrels and/or wheel faces.

- Open the coating bottle and begin by dispensing numerous drops of the liquid onto the supplied Micro Silk applicator to sufficiently wet it. Work the product into the surface, ensuring full coverage over the desired area, using cross hatching motions and overlapping your previous pass by 25-50%. During your time between passes, utilize Adam’s UV Flashlight for inspections. Take note of behind the spokes, in between the crevices of the wheel design, around the valve stem and center cap areas. To ensure a thorough application, the light should shine and reveal an even and consistent bluish hue of light. If you notice streaking in the surfaces, level out with additional product and the used Micro Silk applicator.

- Once the recently applied product begins to characteristically flash and sweat into beads, begin wiping the coating off, applying minimal pressure to the towel in the process. Wipe down in a similar cross hatch pattern as applied, switching/flipping the towel periodically to use a new face to fully level the coating.

- Once fully leveled, allow the coating to fully cure for 24 hours, free from water, elements, or weathering.

FAQ:

- “Can I Apply the Advanced Formula Over My Existing Coating?”

Yes you can! For a quick installation, you can wipe the vehicle down with Surface Prep and coat it. For a longer lasting, more durable protection we recommend decontaminating the vehicle with clay and or machine polishing prior to applying the new coating.

- “Can I layer this product to make it last longer?”

Yes, of course, but that doesn’t mean layering this product 10 times will make it 10x longer— any application after 3 rounds will render the product redundant and still provide the same hydrophobic effects.

- “What is Ceramic Glow Technology?”

Ceramic Glow Technology™ is Adam’s Polishes Patent-Pending chemistry. It’s a crystalline form of an optical brightener that absorbs energy and emits light as it relaxes back down to a lower energy state.

- “What’s the difference between fluorescence and phosphorescence?”

Length of time that the light is emitted. Said another way, the amount of time it takes for the electrons to relax and quit releasing energy in the form of photons or light.

- “Does the UV Coating act as a durability indicator?”

No, it doesn’t. It’s currently offered as an application aid and utility for visualizing the coating. Lack of glow does not indicate lack of coating.

- “Why does the product glow more intensely on some substrates than others?”

Differences in porosity and the ability of the coating to penetrate and bond to different surfaces will cause different levels of film thickness. The thicker the film, the more intense the glow typically.

- “Will my car glow blue in the sunlight?”

No, because this coating is completely invisible and clear under standard light, the coating will only glow a bluish hue under the 395 NM UV light.

- “Will this coating glow after being “charged” with the UV light?”

No, since this coating is fluorescent and not phosphorescent, it will excite and glow only when the light is shone. Contrarily, “glow in the dark” items have a yellow/greenish hue from phosphorescent dyes-- these slowly become excited under any light and will diminish over the course of a few minutes.

- “What can I use this on? Can I just use this on the whole car?”

Adam’s UV Graphene Ceramic Coating provides protection to an extreme range of areas on your vehicle including Painted surfaces, Trim, Bed Rail Covers, Plastic Engine Bay Components, Headlights, Bed liners, - all are safe to be protected.

- “What happens if I forget a spot or end up with a high-spot?”

If you forget a spot and you catch it in time (10-20 minutes after removal) simply reapply to that area and wipe off after 1-2 minutes. Reactivating the product will allow for easier removal. If left on for longer, we recommend Brilliant Glaze and a microfiber applicator, or machine polishing with Correcting Polish to fully remove the imperfection.

Common Sense Warning:

Adam’s Graphene Ceramic Coating™ Advanced is a semi-permanent ceramic coating. Avoid contact with eyes, nose, and ingestion – always keep away from children! If contact does occur, rinse thoroughly with water and monitor for irritation. If irritation persists, contact a physician.