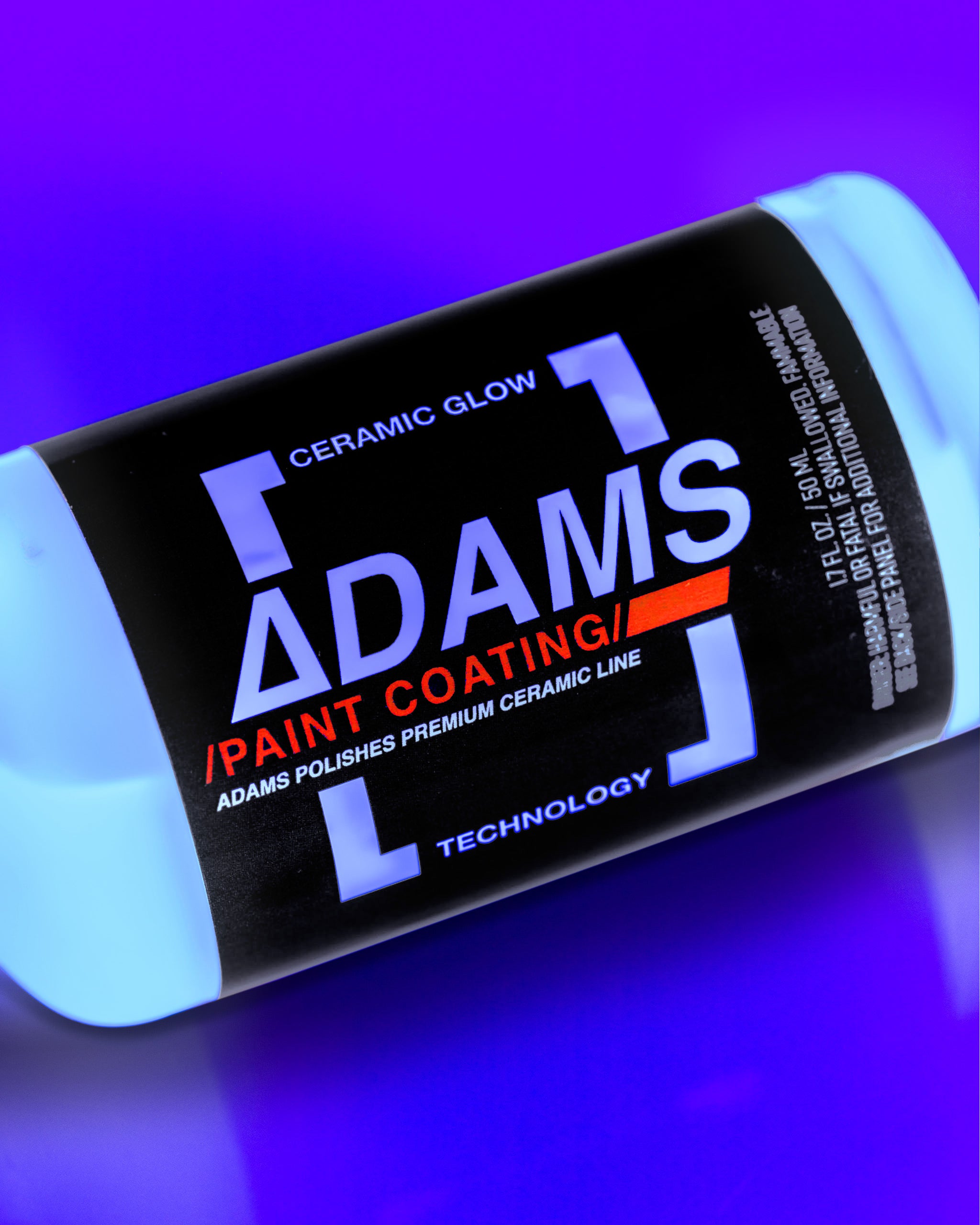

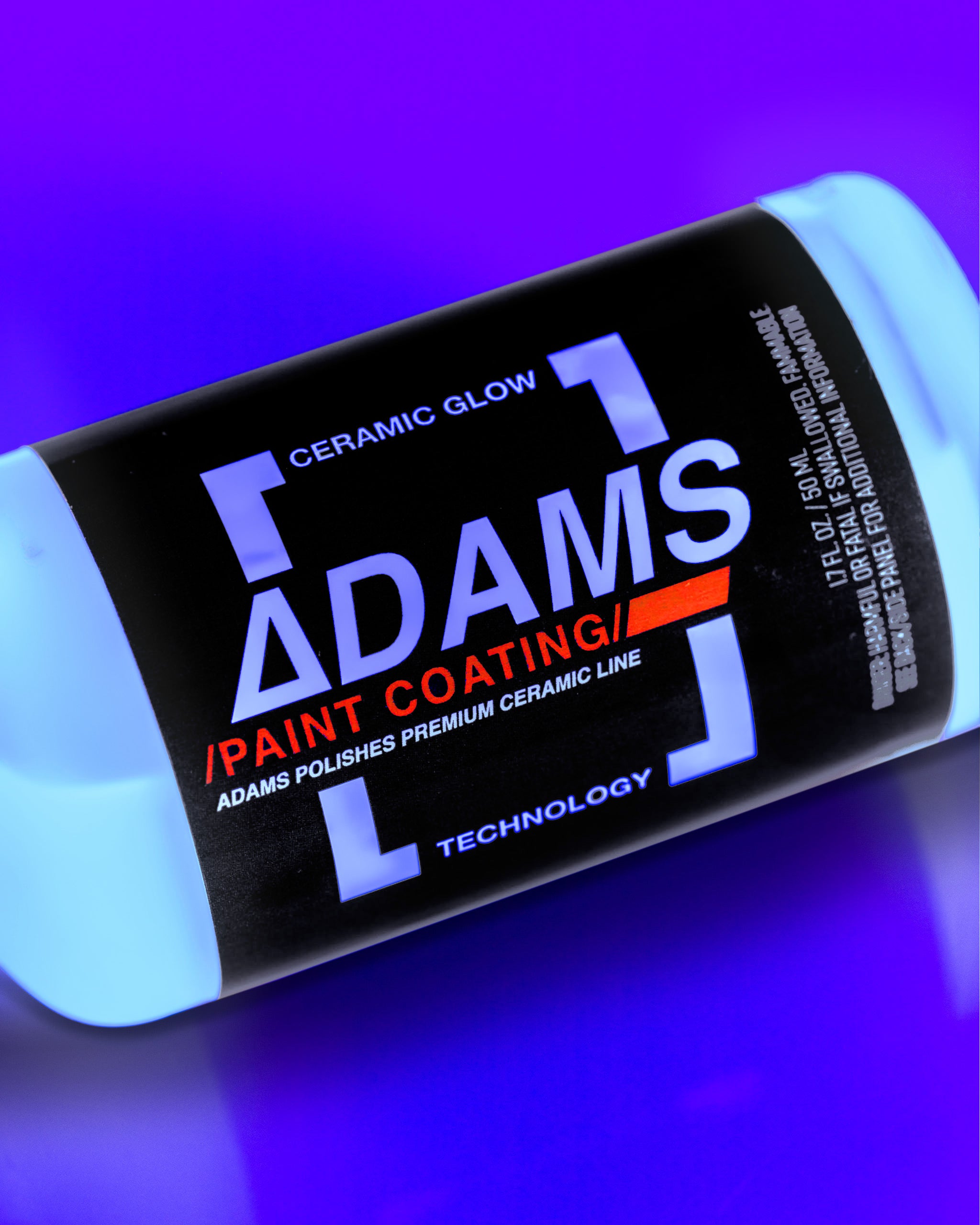

Adam's UV Ceramic Paint Coating

- Patent Pending, UV Tracing technology™

- Enhance Gloss, Depth, and Shine

- Adds Extreme Hydrophobic Effects

- 9H Hardness, 5+ years protection

- 50mL Bottle does 2 full size vehicles

- Extremely durable protection, repels water and elements

- Made in the USA

Adam’s UV Ceramic Paint Coating is a long lasting, durable form of protection for your paint. Providing a 9H hardness and years of protection against the harshest elements you can think of, Adam’s UV Ceramic Paint Coating has increased longevity, but the ending result of the finished coating is significantly slicker! In addition to the formulary upgrades, this product has been infused with patent-pending Ceramic Glow Technology-- this unique feature not only plays the role of an application aid for first-time users but also allows professionals to sharpen their skills with the incredibly thorough application.

We currently offer free shipping in the continental US on orders over $75 after discounts or $7 Flat Rate Shipping. If you don't love what you receive, we'll cover shipping back to our door too. Please note, free returns are not included on international orders.

When looking at our 3 different offerings of coatings, it’s best to think of them in terms of thickness/ overall durability. Our Spray Coating and Wheel Coating are varying formulations of coatings, Wheel being the thicker of the two, but designed especially to hold up against the harshest elements. With Adam’s UV Ceramic Paint Coating, it’s the slickest and glossiest of the formulations to have the most premium form of protection for your paint. As with all of Adam’s Ceramic formulations, these products are tested to the harshest alkaline and acid conditions prior to any real-life testing, meaning you’re getting a durable, versatile, and long-lasting coating!

Adam’s UV Ceramic Paint Coating is a simple, ready to use system that combines versatility with ease of use. Throughout the time that we have offered a Ceramic Paint coating, we currently have offered single soft towels or borderless grey towels depending on the kit, but we’ve learned the plusher the towel the more oils are taken away during the process.

Adam’s Ceramic Paint Coating with UV removes the risks of missed sections and improper application. Upon application, you will use the same process as usual except now you have the ability to shine a UV light and indicate where you’ve applied the product, uneven areas, and a final wipe down inspection to ensure no spots are left behind. This technology and unique chemistry was developed to make the process of ceramic coatings easier for the everyday user, and more thorough for the professional to ensure a thorough application is utilized. Not only will you be saving time during your ceramic coating process, but this technology will help you to master your skills and assurance in your craft.

The process still remains the same as this product looks completely invisible in your everyday environment! During the application process, the longer the coating rainbows and is exposed to more oxygen the more this coating will glow under UV light. This product goes on clear and under the radar, however, under 395 NM UV Light your unveiling the presence of the coating. With that being said, your regular maintenance washes have the ability to showcase your coating’s prominence on the surface and let you know if a “re-up” of our ceramic maintenance items are needed!

Adam’s UV Ceramic Paint Coating can be used on a single stage, clear-coated, and vinyl wraps. This product should be applied in temperatures above 50 degrees and allowed to cure for 12-24 hours at a minimum. This kit is designed to be user-friendly and allow any consumer to apply a durable Ceramic Paint Coating with ease.

FAQ’s

“Can I layer this product to make it last longer?” Yes, of course, but that doesn’t mean layering this product 10 times will make it 10x longer— any application after 3 rounds will render the product redundant and still provide the same hydrophobic effects.

“What is Ceramic Glow Technology?” Ceramic Glow Technology is Adam’s Polishes Patent-Pending chemistry. It’s a crystalline form of an optical brightener that absorbs energy and emits light as it relaxes back down to a lower energy state.

“What’s the difference between fluorescence and phosphorescence?” Length of time that the light is emitted. Said another way, the amount of time it takes for the electrons to relax and quit releasing energy in the form of photons or light.

“Does the UV Coating act as a durability indicator?” No, it doesn’t. It’s currently offered as an application aid and utility for visualizing the coating. Lack of glow does not indicate lack of coating.

“Why does the product glow more intensely on some substrates than others?” Differences in porosity and the ability of the coating to penetrate and bond to different surfaces will cause different levels of film thickness. The thicker the film, the more intense the glow typically.

“Will my car glow blue in the sunlight?” No, because this coating is completely invisible and clear under standard light, the coating will only glow a bluish hue under the 395 NM UV light.

“Will this coating glow after being “charged” with the UV light?” No, since this coating is fluorescent and not phosphorescent, it will excite and glow only when the light is shone. Contrarily, “glow in the dark” items have a yellow/greenish hue from phosphorescent dyes-- these slowly become excited under any light and will diminish over the course of a few minutes.

“What can I use this on? Can I just use this on the whole car?” Adam’s UV Ceramic Paint Coating provides protection to an extreme range of areas on your vehicle. Painted surfaces, Trim, Bed Rail Covers, Plastic Engine Bay Components,Headlights, Bed liners, Tonneau covers, Canvas tops, Floor mats— All are safe to be protected.

“What happens if I forget a spot or end up with a high-spot?” If you forget a spot and you catch it in time (10-20 minutes after removal) simply reapply to that area and wipe off after 1-2 minutes. Reactivating the product will allow for easier removal. If left on for longer, we recommend Brilliant Glaze and a microfiber applicator, or machine polishing with Correcting Polish to fully remove the imperfection.

In the detailing world, it’s become testament that preparation is key. Caring for your towels properly, polishing paint to perfection before ceramic coatings, claying the surface before applying wax… Detailing is a combination of compounding steps to ensure a perfect finish is achieved and properly maintained. The highest achievable rank of protection we have to offer is our state-of-the-art ceramic coatings, which require multiple steps to ensure a flawless application. The last step before the ceramic coating process is a thorough wipe with an IPA (Isopropyl Alcohol) based solution to remove any existing residues or surface contaminants left behind during the polishing process. If this step isn’t executed properly, all the hard work and efforts you’ve previously performed can all go to waste.

In the kit you’ll find:

1- 50ml UV Paint Coating Bottle

1- 4oz Ceramic Boost

1- 4oz Surface Prep

2- Surface Prep Towels

2- Removal Towels

2- Micro Silk Applicators

1- Pair of Gloves

For Use on Paint:

Step 1: Remove the 4oz bottle of Adam’s Surface Prep and supplied Towel and fold towel into fourths. Prepare your paint and use the supplied 4oz bottle of Adam’s Surface Prep and Surface Prep towel to clean and degrease the surface of any existing protection or residual films. Spritz each surface with a direct spray and once into the towel to optimally clean the surface. For optimal results, users must Wash, Clay/Decontaminate, and Polish their paint for best results.

Step 2: Remove the supplied UV Ceramic Paint Coating bottle from the packaging and the pair of supplied gloves. With the gloves on, open and begin to dispense the coating onto the supplied Micro Silk applicator and begin the coating process. Begin to work the product into the surface, ensuring full coverage over the desired area. Cross hatching motions are favored during this process and overlapping your previous pass by 50%. During your time between passes, utilize Adam’s UV Handheld light for inspections. Take note of between the body lines, bumper areas, mirror caps, and commonly missed areas on your vehicle. To ensure a thorough application, the light should shine and reveal an even and consistent bluish hue of light. If you notice streaking in the surfaces, level out with additional product and the used Micro Silk applicator.

Step 3: To begin the removal process, remove 1 of the supplied coating removal towels from the packaging and fold the towel into fourths. Begin wiping the coating and applying minimal pressure to the towel. Once fully removed, allow the coating to fully cure for 24 hours, free from elements or weathering. Not allowing optimal time will force the coating to cure with whatever elements touches it during the curing process. Once fully cured, you’re free to enjoy the open road and have coated, perfected paint no matter how harsh the conditions.

Step 4 (Optional): To give your coating that extra pop after application, spray Adam’s Ceramic Boost to the coating to top the coating with an added layer of silica enhancement. Apply as needed.

For Use on Plastic & Trim:

Step 1: Remove the 4oz bottle of Adam’s Surface Prep and supplied Edgeless Utility Towel and fold towel into fourths. Prepare your trim and use the supplied 4oz bottle of Adam’s Surface Prep and edgeless utility towel to clean and degrease the surface of any existing protection or residual films. Spritz each surface with a direct spray and once into the towel to optimally clean the surface. For heavily contaminated trim and plastic, we recommend a deep cleanse with Tire & Rubber Cleaner and an edgeless utility towel.

Step 2: Remove the supplied UV Ceramic Paint Coating bottle from the packaging and the pair of supplied gloves. With the gloves on, open and open the bottle and begin dispensing the chemical onto the supplied micro silk applicator to begin the coating process. Begin to work the product into the surface, ensuring full coverage over the desired area. Since the product is being applied to a porous plastic surface, you will not see a rainbow/ flashing effect— the immediate color change of the plastic or trim will reveal where the product has been applied.

Step 3: Allow coating to fully cure for 1-2 hours, free from elements or weathering. Not allowing optimal time will force the coating to cure with whatever elements touches it during the curing process. Once cured, you’re free to enjoy the open road and have clean, dressed plastic & trim no matter how harsh the conditions.