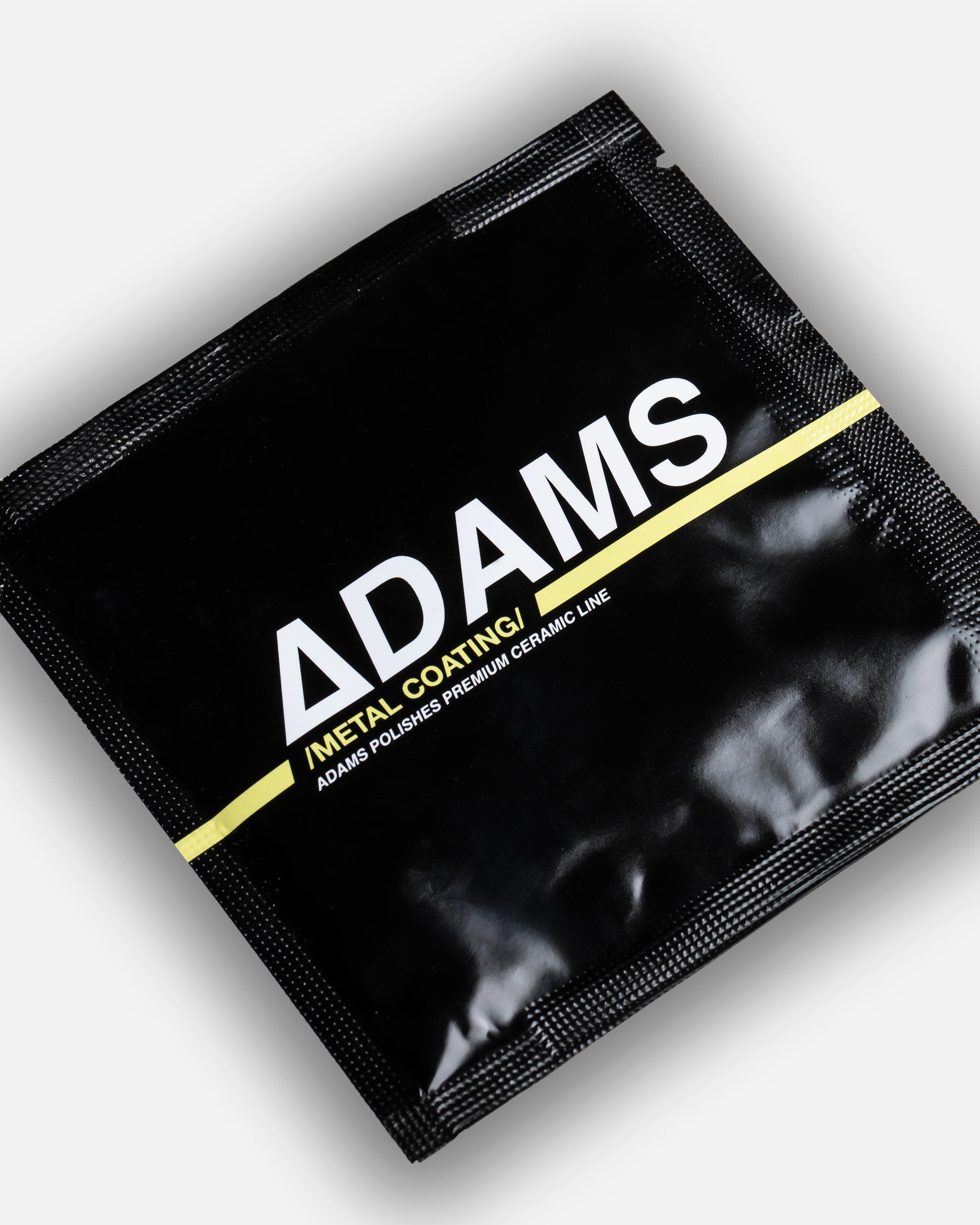

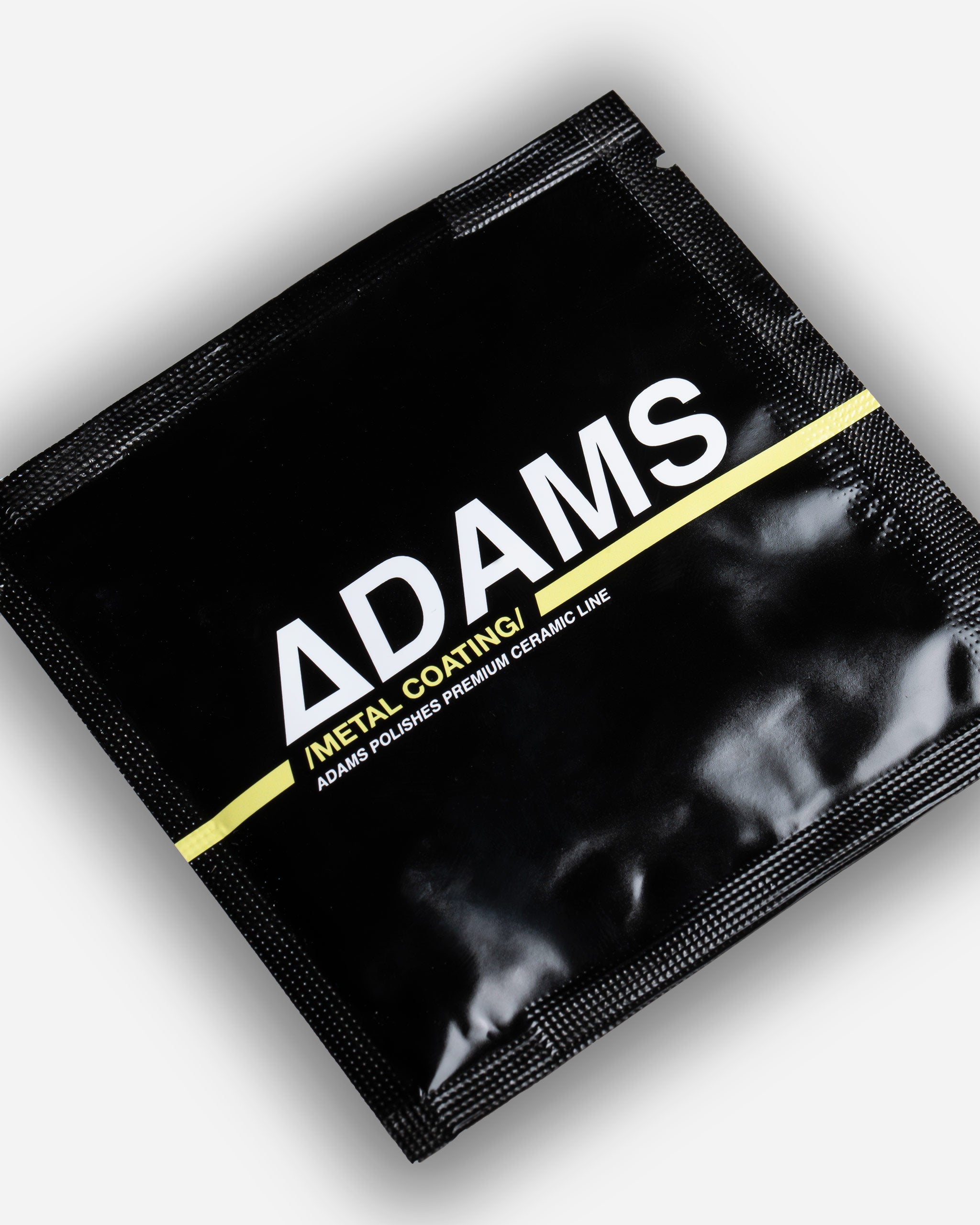

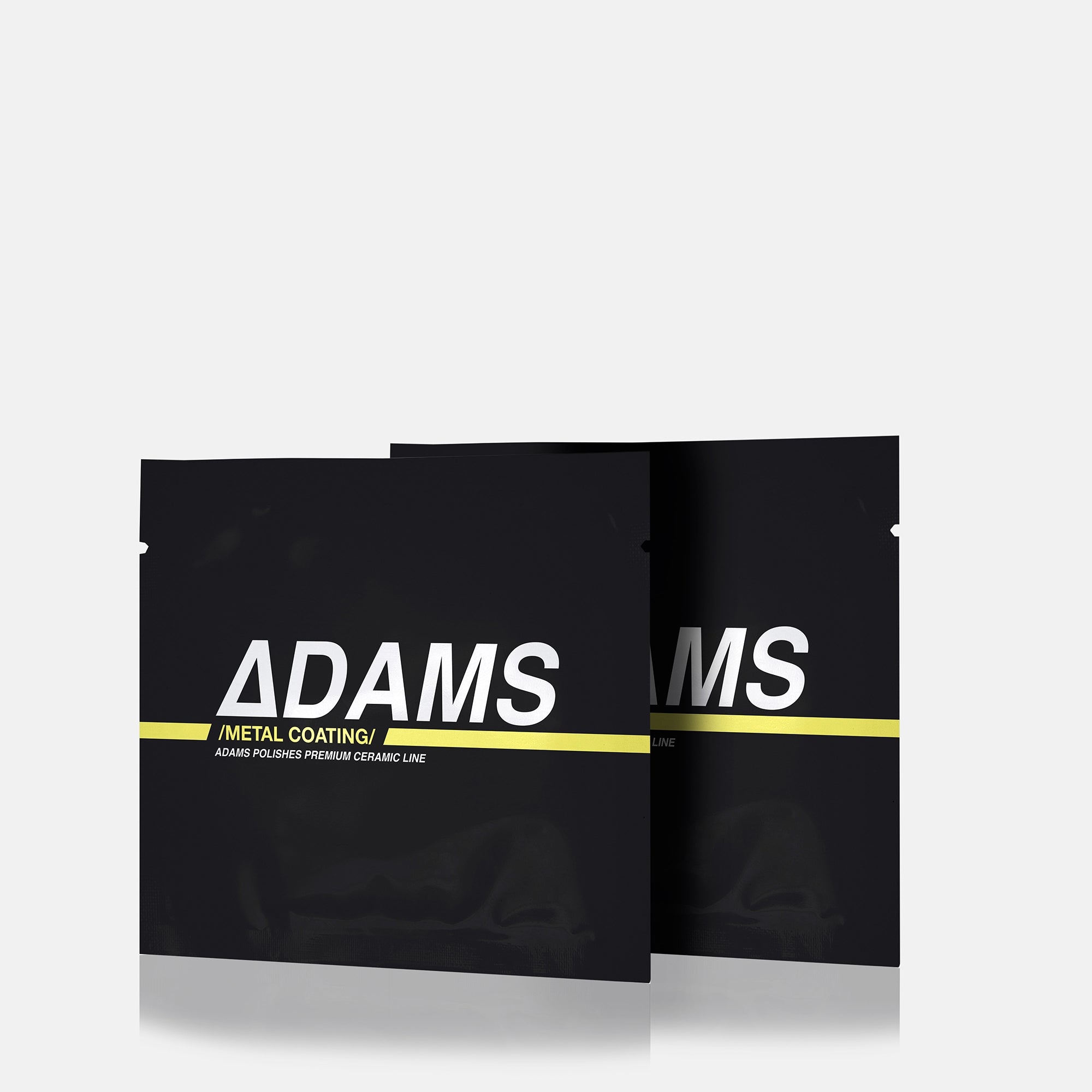

Ceramic Metal Coating Wipe

Provides long-lasting, extreme hydrophobic effects for aluminum, stainless steel, and other metal surfaces. Adam’s Ceramic Metal Coating is a simple, ready to use system that combines versatility with ease of use. In the kit, you find everything you need to both effectively prepare metal surfaces for the coating, and apply the coating all in one procedure.

- Saturated Ceramic Wipe

- 9H Metal Ceramic Coating

- Wipe on, Walk Away Formula

- Covers 4x4 Surface Area

- Mesh Wipe Material

- Made in the USA

We currently offer free shipping in the continental US on orders over $75 after discounts or $7 Flat Rate Shipping. If you don't love what you receive, we'll cover shipping back to our door too. Please note, free returns are not included on international orders.

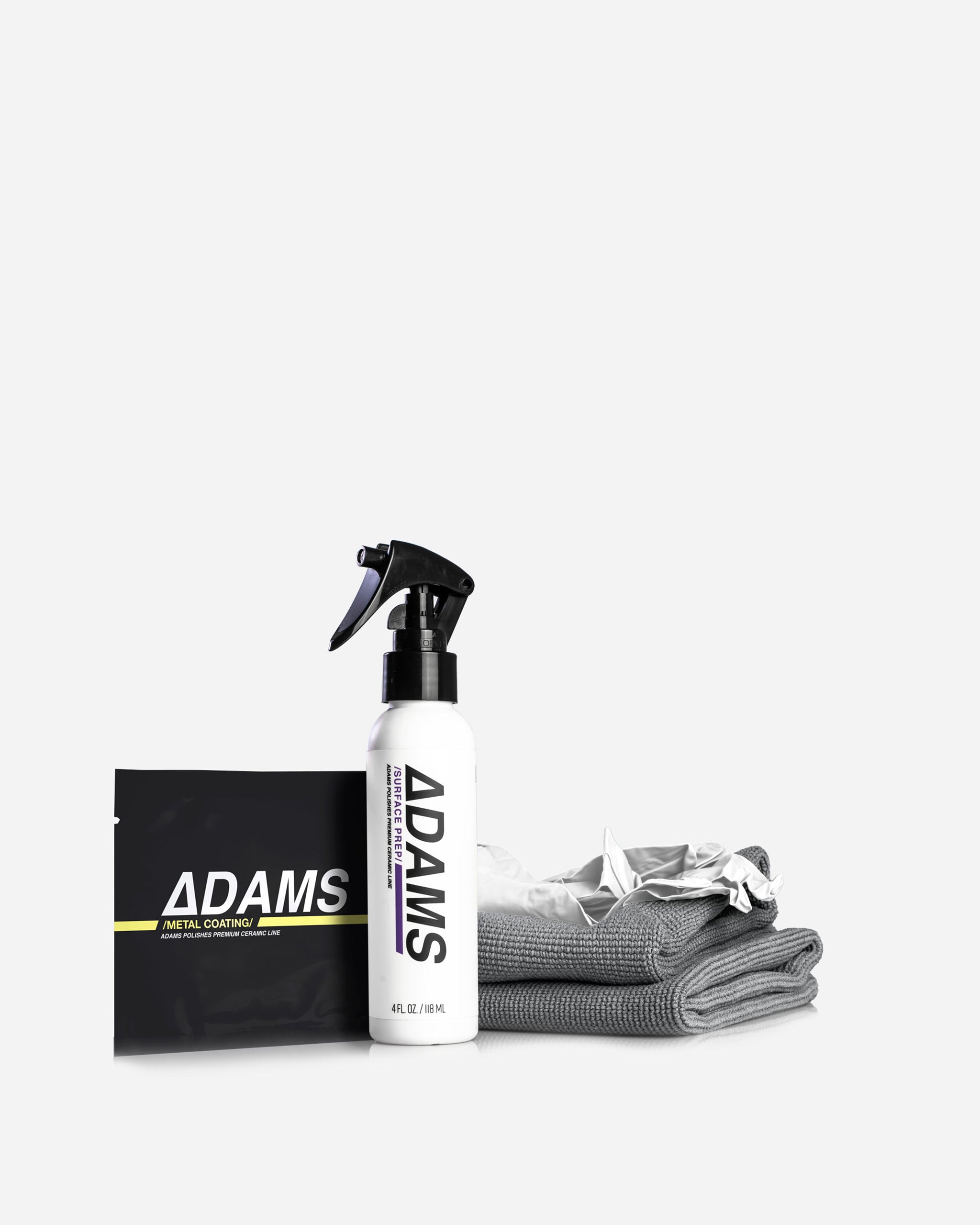

Kit Contents:

- 2 Metal Coating Wipes

- 2 Edgeless Utility Towels

- 2 White Gloves

- 4oz Surface Prep

- Instruction Sheet

The introduction of Ceramic Wipes into the industry will greatly reduce the amount of time you spend on each coating application by easily applying the product and walking away without the need for buffing it away! Not only does this control overusing chemicals, but it makes cleanup a breeze as you dispose of the wipe after use. Our current offering of coatings can work on metal substrates, however, you will need to buff off the excess surface oils and residues.

For Use on Metal:

Step 1: Use Adam’s Surface Prep and Edgeless Utility Towel and fold the towel into fourths. Prepare your metal and use Adam’s Surface Prep and Edgeless Utility Towel to clean and degrease the surface of any existing protection or residual films. Spritz each surface with a direct spray and once into the towel to optimally clean the surface. For oxidized and dull metal, polish to perfection with Adam’s Metal Polish 1 & 2 and a microfiber applicator.

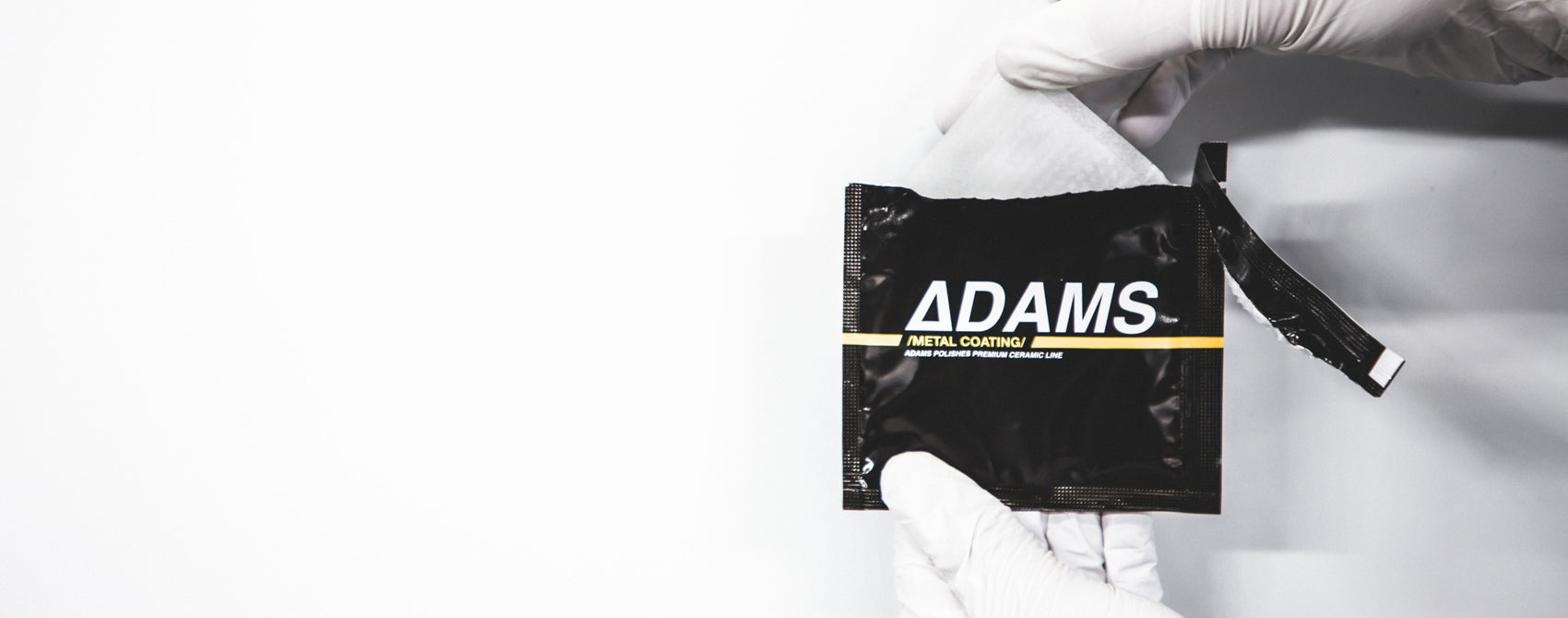

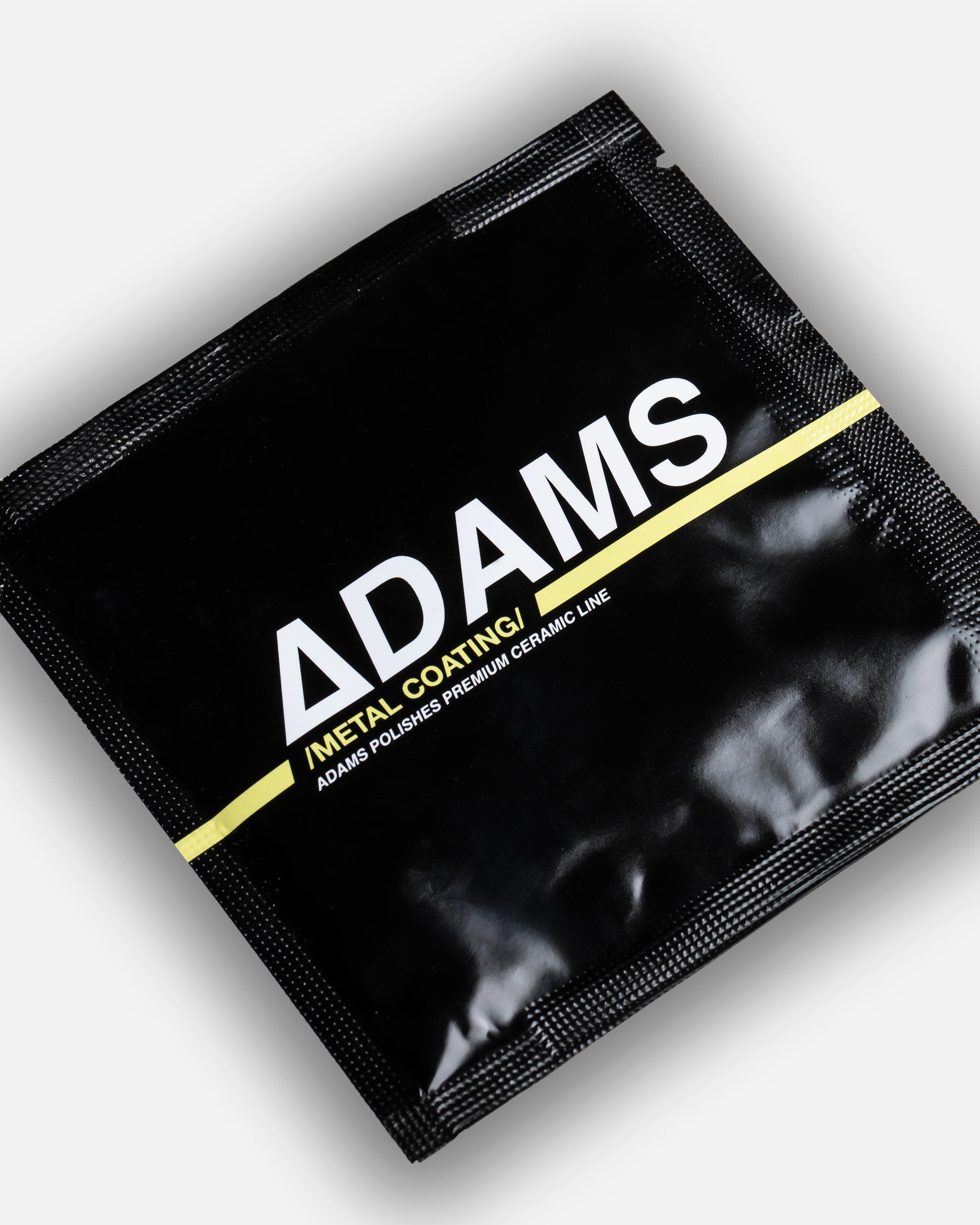

Step 2: Tear Open the Ceramic Metal wipe from the packaging and put on pair of gloves. With the gloves on, open and remove the contents of the wipe and begin the coating process. Begin to work the product into the surface, ensuring full coverage over the desired area. As this coating is a wipe on and walk away process, you will notice the product begin to flash and eventually rainbow out after 3-5 minutes depending on the surface.

Step 3: Allow coating to fully cure for 1-2 hours, free from elements or weathering. Not allowing optimal time will force the coating to cure with whatever elements touches it during the curing process. Once cured, you’re free to enjoy the open road and have clean, protected metal surfaces no matter how harsh the conditions.