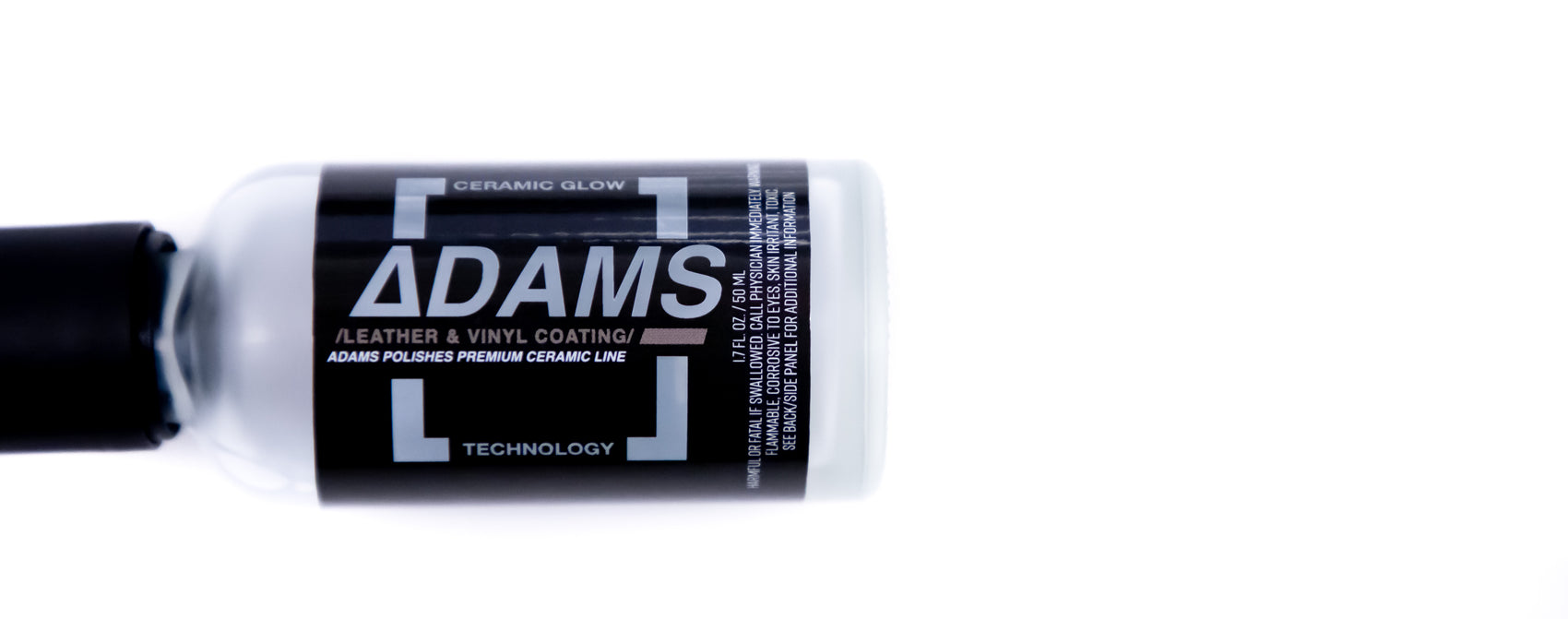

Adam's UV Leather & Vinyl Coating

Adam’s UV Leather & Vinyl Ceramic Coating is our first offering of a ceramic coating for interior surfaces! Much like our other UV ceramic coating offerings, the UV tracer allows you to see where the coating is applied when used with the Adam’s UV Flashlight. Adam’s UV Leather & Vinyl is specifically formulated for natural, sealed and synthetic leathers and vinyl surfaces including your dash, door panels and other hard interior surfaces. This product is not suitable for aniline leathers or for use over the top of Adam’s Leather Conditioner!

- Patent Pending, UV Tracing Technology™

- Rapid Cure – Fast Flash & Low VOC

- Extremely Easy to Use – Wipe On / Wipe Off

- Provides Extreme Hydrophobicity, Wear and UV Protection

- 50 mL Bottle Does Multiple Automotive Interiors

We currently offer free shipping in the continental US on orders over $75 after discounts or $7 Flat Rate Shipping. If you don't love what you receive, we'll cover shipping back to our door too. Please note, free returns are not included on international orders.

Adam’s UV Leather & Vinyl Ceramic Coating provides semi-permanent protection to surfaces via the curable ceramic resins loaded into the easy to use formula. The active Ceramic Glow Technology™, with use of the Adam’s UV Flashlight, provides unrivaled levels of visibility of the coating during and after application for peace of mind that the coating has been thoroughly applied and is providing lasting protection.

Adam’s UV Leather & Vinyl Ceramic Coating will provide leather seats and other hard interior surfaces protection from everyday wear and tear, ultraviolet damage, jean transfer, color fading, stains and spills. This coating is at its best when it is used proactively to prevent damage and is not as good for use on already deteriorated surfaces.

Instructions for Application & General Use:

- Utilize any of Adam’s Leather & Interior Cleaner, Adam’s Interior Cleaning Wipes or Adam’s All Purpose Interior Cleaning Gel with an Adam’s Interior Microfiber Towel to ensure surface to be protected is clean and dry before application of the coating.

- Lightly saturate a Gray Suede Applicator or similar with numerous drops of the coating.

- On a subsection of surface to be protected such as part of a seat or door panel, wipe the applicator across the surface using a cross-hatch motion with slight overlap to sufficiently ensure coverage. Using the Adam’s UV Flashlight in this step helps ensure proper leveling and coverage.

- After allowing the coating to flash or volatilize and penetrate for 60 seconds, wipe excess material from the surface until dry using a clean, dry Adam’s Interior Microfiber Towel or an Adam’s Suede Microfiber Towel. The coating should be dry to the touch and a uniform blue glow should be evident on the subsection when using the Adam’s UV Flashlight.

- Repeat alternating Steps 2, 3 and 4 on additional surfaces until it is evident that all areas requiring protection are complete.

- If any unpleasant odors are present, ventilate vehicle and odor will dissipate. Odor is not harmful or hazardous.

When Cleaning a Spill:

- To preserve the life of the coating and promote maximum durability, blot out spills with a clean, dry microfiber towel and avoid aggressively rubbing the surface.

Common Sense Warning:

Adam’s UV Leather & Vinyl Ceramic Coating is a semi-permanent ceramic coating and should not be used on any textiles or aniline leather surfaces due to their fibrous nature. The coating will ruin the look and feel of these surfaces and won’t perform as intended. Always apply a coating to an inconspicuous area first to ensure compatibility.

FAQ:

Q:“Can I layer this product to make it last longer?”

A: Yes, but it is inadvisable to layer multiple times on leather surfaces. Multiple coats of a ceramic coating on leather can be expected to harden the leather and make it less supple and flexible making it brittle and rough.

Q: “What is Ceramic Glow Technology?”

A: Ceramic Glow Technology™ is Adam’s Polishes Patent-Pending chemistry utilizing a unique UV tracer within the formula. It’s a crystalline form of an optical brightener that absorbs energy and emits light as it relaxes in energy states.

Q: “What’s the difference between fluorescence and phosphorescence?”

A: The length of the emission of light. Fluorescence is effectively instantaneous and phosphorescence, or glow in the dark as it’s also known, emits much more slowly over a prolonged period of time.

Q: “Does the UV tracer act as a durability indicator?”

A: No, it doesn’t. It’s currently offered as an application aid and utility for visualizing the coating. Lack of glow does not necessarily indicate a lack of coating.

Q: “Why does the product glow more intensely on some substrates than others?”

A: Differences in porosity and the ability of the coating to penetrate and bond to different surfaces will cause different levels of film thickness. The thicker the film, the more intense the glow, typically.

Q: “Will surfaces protected with the coating glow in the sunlight?”

A: No, because this coating is completely invisible and clear under standard light, the coating will only glow a blueish hue under 395 nm UV light.

Q: “Will this coating glow after being “charged” with UV light?”

A: No, this coating contains a fluorescing optical brightener and not phosphorescent.